Factory-direct custom square silk scarf production tailored for fashion brands, designers, retailers, and corporate gifting programs.

We support leading global brands with factory-direct, high-quality custom silk solutions.

From concept to production, we create premium custom silk scarves for promotions, gifting, and brand campaigns.

WiseSilk delivers factory-direct custom square silk scarves with full-service support, covering fabric selection, printing, finishing, and packaging — all produced with consistent quality and flexible order quantities to match your brand positioning.

From initial concept to finished scarves, each step is handled with precision, efficiency, and full transparency.

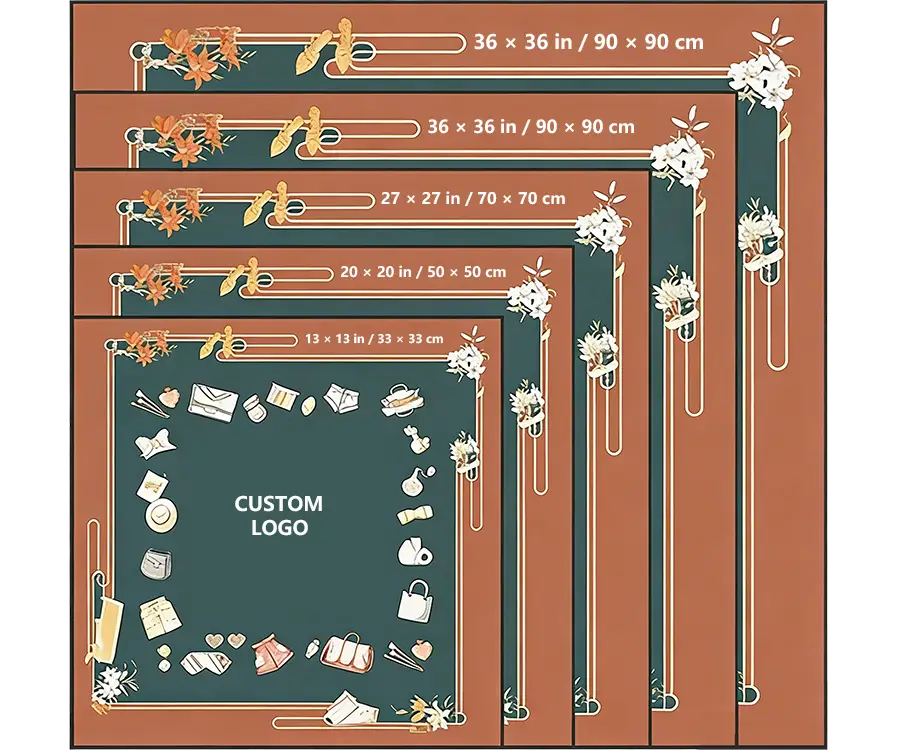

We offer custom square silk scarves in standard and bespoke sizes to suit different styling and brand needs.

All dimensions can be adjusted based on design layout, wearing style, and brand requirements.

A wide range of high-quality silk fabrics is available:

(14–16 momme is recommended for most square silk scarves)

The following three custom silk scarf solutions are the most popular choices among brands and designers.

Brand personalization options include:

Sustainable and eco-friendly packaging solutions are also available upon request.

All custom square silk scarves are produced in-house at our professional silk manufacturing facility.

Quality control covers every stage, including:

Production complies with international standards, including OEKO-TEX® Standard 100, BSCI, SGS, Intertek, and WRAP.

Bring your designs to life with premium custom square silk scarves made for elegance and brand recognition.

Get a Free QuoteFind answers to your silk customization and production questions.

We use 100% mulberry silk for all custom square silk scarves, with multiple fabric options available to suit different design styles, finishes, and budgets.

Common silk fabric options include:

Momme weight options:

Our team can recommend the most suitable fabric and momme combination based on your scarf size, artwork style, usage scenario, and brand positioning. Samples are available for confirmation before bulk production.

Single-sided printing is the most commonly used option for custom silk scarves. The design is printed on one side, with natural color penetration visible on the reverse side. It offers vivid colors, a soft hand-feel, stable quality, and cost efficiency.

Double-sided printing involves printing both sides of the silk scarf, allowing the same or different designs on each side. This method delivers a more premium visual effect but requires higher precision, longer production time, and increased cost.

Factory recommendation:

We can provide sample comparisons during the sampling stage to help you choose the most suitable printing solution.